9. Hydraulic System Operation And Troubleshooting

Topic 9 - HYDRAULIC SYSTEM OPERATION AND TROUBLESHOOTING

INTRODUCTION

Hydraulic systems are widely used in various manufacturing industries. The diversity of hydraulic components and control techniques varies depending on the application area. Understanding of operating systems, symbols, control valves and safe operation procedures is important for people involved in monitoring hydraulic system for production operation.

This course explains the underlying principles of fluid power generation and controls in relation to practical systems. It is a guide to the details that are so important in understanding the complete hydraulic operation principles and identifying abnormalities for countermeasure

COURSE OBJECTIVE

After attending this course, participants will be able to :

WHO SHOULD ATTEND

The course is designed for Technicians and Maintenance Personnel who are responsible for the operation and maintenance of hydraulics system.

DURATION

The duration of the course is 1 day

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

The course will be conducted in the form of theory, discussion and exercises.

COURSE CONTENT

DAY 1

SESSION 1- INTRODUCTION TO HYDRAULIC SYSTEM

SESSION 2 – HYDRAULIC POWER GENERATION

SESSION 3 – CONTROL VALVES

SESSION 4 - ACTUATORS

SESSION 5 – FAULT FINDING AND TROUBLESHOOTING

INTRODUCTION

Hydraulic systems are widely used in various manufacturing industries. The diversity of hydraulic components and control techniques varies depending on the application area. Understanding of operating systems, symbols, control valves and safe operation procedures is important for people involved in monitoring hydraulic system for production operation.

This course explains the underlying principles of fluid power generation and controls in relation to practical systems. It is a guide to the details that are so important in understanding the complete hydraulic operation principles and identifying abnormalities for countermeasure

COURSE OBJECTIVE

After attending this course, participants will be able to :

- Understand the basic principles of hydraulic system

- Know the functions of the various types of control valves

- Be able to read & interpret hydraulic symbols and circuits

- Understand the construction and operation of hydraulic pump

- Identify the hydraulic components and will know their function

- Carry out basic routine inspection of hydraulic system.

- Realize the potential hazards in hydraulic and work safely

WHO SHOULD ATTEND

The course is designed for Technicians and Maintenance Personnel who are responsible for the operation and maintenance of hydraulics system.

DURATION

The duration of the course is 1 day

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

The course will be conducted in the form of theory, discussion and exercises.

COURSE CONTENT

DAY 1

SESSION 1- INTRODUCTION TO HYDRAULIC SYSTEM

- Pascal’s law

- Pressure, Force, & Area

- Pressure and Flow

- How pressure is created

- Safety in hydraulic system

SESSION 2 – HYDRAULIC POWER GENERATION

- Hydraulic Fluid – Viscosity and Quantity

- Oil Level Indicator, Filters and strainers

- Temperature indicator

- Electric motor

- Hydraulic Pump – Gear pump

- Heat Exchanger / Oil Cooler

- Hydraulic Hoses

SESSION 3 – CONTROL VALVES

- Pressure relief valve, Flow Control Valve & Check Valve

- Directional control valves – 4/2way valve, 4/3way valve

- Solenoid Operated Valves – Single acting, Double acting

- Hydraulic valves & component symbols

- Reading and Understanding Hydraulic schematic

SESSION 4 - ACTUATORS

- Single and Double acting cylinder

- Operating principles

- Problem ,causes and remedy

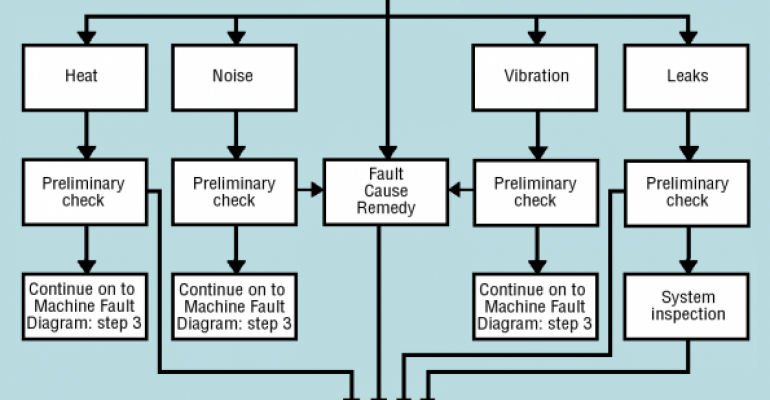

SESSION 5 – FAULT FINDING AND TROUBLESHOOTING

- Systematic Fault Tracing & Troubleshooting

- Types of problems, causes and remedy

- Hydraulic system inspection

- Condition monitoring inspection tools

- Check sheets, Lubricant replacement