4. Maintenance Of Gearbox And Speed Reducers

Topic 4 - MAINTENANCE & INSPECTION OF INDUSTRIAL GEARBOX

AND SPEED REDUCERS

INTRODUCTION

Practically all equipment that moves in today's industry does so by means of power-transmission equipment. The installation, adjustment and maintenance of this vital equipment are the technicians or mechanic's job. To perform this job well, he or she must have an understanding of the basic principles and the concept of operation, as well as a practical knowledge of work procedures. Although there are many systems and an infinite number of design variations, the terms and concepts that apply to all are relatively simple.

The term power-transmission equipment applies to specific parts of a machine assembly which functions as a mechanical transmission of power. The most common form is the transmission of power from shaft to shaft. This can be broken into two types of rotary-motion power transmission: shaft to shaft axially and shaft to adjacent shaft.

COURSE OBJECTIVES

After the completion of this course, participant will be able to

WHO SHOULD ATTEND

The course is designed for Technicians and Mechanics who are responsible for the maintenance, inspection and repair of gearboxes

DURATION

The duration of this course is 2 days

COMMENCEMENT DATE AND VENUE

The course will commence on dates/days suitable to your organization at your premises.

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

To gauge the knowledge possessed by the trainees, we will conduct a pre and post test.

The course will be conducted in the form of applied theory, demonstrations, and practical exercises.

FACILITATOR

The course will be conducted by Mr W.E who has 20 years of experience working in maintenance and plant engineering and had handled various types of speed reducers by guiding technicians and engineers to perform the correct inspection and servicing of speed reducers as to enhance equipment efficiency.

DAY 1

PRACTICAL:

1. Inspection of speed reducers at the factory

2. Dismantling, inspection and assembly of speed reducers

3. Inspection of shaft runout using measurement tool

4, Obtaining backlash measurement of speed reducer

AND SPEED REDUCERS

INTRODUCTION

Practically all equipment that moves in today's industry does so by means of power-transmission equipment. The installation, adjustment and maintenance of this vital equipment are the technicians or mechanic's job. To perform this job well, he or she must have an understanding of the basic principles and the concept of operation, as well as a practical knowledge of work procedures. Although there are many systems and an infinite number of design variations, the terms and concepts that apply to all are relatively simple.

The term power-transmission equipment applies to specific parts of a machine assembly which functions as a mechanical transmission of power. The most common form is the transmission of power from shaft to shaft. This can be broken into two types of rotary-motion power transmission: shaft to shaft axially and shaft to adjacent shaft.

COURSE OBJECTIVES

After the completion of this course, participant will be able to

- Understand the construction, assembly and function of gearbox

- Apply effective inspection methods of gearbox

- Check shaft end play and gear backlash measurements

- Apply good gearbox maintenance practices to extend it’s lifespan

- Perform correct input output shaft alignment setting

WHO SHOULD ATTEND

The course is designed for Technicians and Mechanics who are responsible for the maintenance, inspection and repair of gearboxes

DURATION

The duration of this course is 2 days

COMMENCEMENT DATE AND VENUE

The course will commence on dates/days suitable to your organization at your premises.

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

To gauge the knowledge possessed by the trainees, we will conduct a pre and post test.

The course will be conducted in the form of applied theory, demonstrations, and practical exercises.

FACILITATOR

The course will be conducted by Mr W.E who has 20 years of experience working in maintenance and plant engineering and had handled various types of speed reducers by guiding technicians and engineers to perform the correct inspection and servicing of speed reducers as to enhance equipment efficiency.

DAY 1

- (1) INTRODUCTION TO MAINTENANCE OF GEARBOX

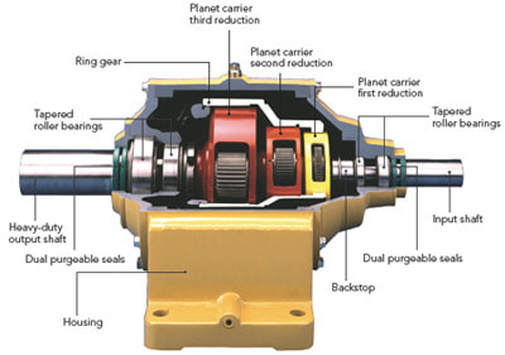

- Construction of gearbox

- Purpose and function of gearbox

- Torque and speed converter

- Component parts

- Gearbox housing material

- Construction of gearbox

- (2) GEARING

- Calculation of speed ratio and speed

- Backlash and measurement method

- Gear Materials and Heat Treatment

- Types of gears

- (3) INSTALLATION AND MAINTENANCE OF GEARS

- Mounting and Installation of Gears

- Assembly of gears and setting

- Installation and Start-Up of Enclosed Gear Drives

- Gear backlash and shaft end play

- Load and No load gear contact pattern

- (4) GEARBOX LUBRICATION

- Co efficient of friction

- Lubrication selection

- Lubrication methods

- Oil change schedules

- Gearbox oil analysis

- (5) BEARING MAINTENANCE IN GEARBOX

- Types of bearings

- Installation method

- Bearing inspection

- Failure symptoms

- Maintenance practice

- (6) GEARBOX INSPECTION

- Inspection sheet

- Walkabout visual inspection

- Detecting vibration, abnormal sound and heat

- Gearbox inspection methods

- Breather and shaft seal inspection

- Examine through inspection port

- (7) COUPLING AND SHAFT ALIGNMENT

- Chain and Elastomeric Coupling

- Shaft parallel and angular alignment

- Symptoms Found On Inspection

- Causes Of Failure And Troubleshooting

- (8) MAINTENANCE, FAILURE CAUSES AND REMEDY

- Maintaining service record and history card

- Failure causes and remedy

PRACTICAL:

1. Inspection of speed reducers at the factory

2. Dismantling, inspection and assembly of speed reducers

3. Inspection of shaft runout using measurement tool

4, Obtaining backlash measurement of speed reducer