11. Rigging, Slinging and Overhead Crane Operation Safety

TOPIC 11- RIGGING, SLINGING & OVERHEAD CRANE OPERATION SAFETY

INTRODUCTION

Health and safety legislation such as the Factories and Machinery Act 1967 has concentrated on the provision and maintenance by an employer of a safe place of work. This has been accomplished by the continuing enforcement of legal requirements applied to machinery and work equipment.

The Occupational Safety and Health Act 1994, in Health and Safety Legislation, brought in a human factors related approach to occupational health and safety, along with the general duty of employers to actually manage health and safety at work.

Workers who are handling overhead cranes to perform their daily task such as to rig, lift and locate items from one place to another, need to trained and assessed in the proper method of handling and inspection of crane and its related parts such as chain hooks, slings, wire ropes before performing any task as to prevent accident and near misses.

This course will create safety awareness and work safely culture with workers who handle overhead cranes.

WHO SHOULD ATTEND

This course is designed for:

COURSE OBJECTIVE

Upon completion of the course participants will be able to :

Course will be conducted in form of class activity and practical at worksite.

The course will be conducted in Bahasa Malaysia

DURATION

The duration of the course is 2 day.

COMMENCEMENT DATE AND VENUE

The course can be conducted on day selected by your organisation

ASSESSMENT

Post test will be conducted to assess trainees understanding before and after attending the training.

Practical individual assessment will be conducted on day 2 and the results will be submitted together with training completion report.

FACILITATOR

The course will be conducted by Mr W.E, who has vast experience in handling engineering projects and had worked in plant maintenance and engineering for over 20 years and was involved in machinery installation, maintenance and safety controls in equipment and overhead cranes. He has experience in overhead cranes maintenance, inspection and had trained industrial operators, foreign workers, crane operators and technicians from various organizations. He is NIOSH certified competent for Crane Rigging & Slinging.

COURSE CONTENT

DAY 1

PRACTICAL

. Inspection of Rigging & Slinging Equipment

. Overhead Crane Inspection at Site

. Rigging, Slinging & Lifting Loads

DAY 2

PRACTICAL

INTRODUCTION

Health and safety legislation such as the Factories and Machinery Act 1967 has concentrated on the provision and maintenance by an employer of a safe place of work. This has been accomplished by the continuing enforcement of legal requirements applied to machinery and work equipment.

The Occupational Safety and Health Act 1994, in Health and Safety Legislation, brought in a human factors related approach to occupational health and safety, along with the general duty of employers to actually manage health and safety at work.

Workers who are handling overhead cranes to perform their daily task such as to rig, lift and locate items from one place to another, need to trained and assessed in the proper method of handling and inspection of crane and its related parts such as chain hooks, slings, wire ropes before performing any task as to prevent accident and near misses.

This course will create safety awareness and work safely culture with workers who handle overhead cranes.

WHO SHOULD ATTEND

This course is designed for:

- Crane operators

- Supervisors

- Technicians

COURSE OBJECTIVE

Upon completion of the course participants will be able to :

- Know the importance of safety at workplace and apply good practices to avoid accidents

- Understand employee’s responsibilities towards safety at workplace.

- Use signaling as a means of communication in crane operation

- Apply the right method of doing proper rigging and lifting.

Course will be conducted in form of class activity and practical at worksite.

The course will be conducted in Bahasa Malaysia

DURATION

The duration of the course is 2 day.

COMMENCEMENT DATE AND VENUE

The course can be conducted on day selected by your organisation

ASSESSMENT

Post test will be conducted to assess trainees understanding before and after attending the training.

Practical individual assessment will be conducted on day 2 and the results will be submitted together with training completion report.

FACILITATOR

The course will be conducted by Mr W.E, who has vast experience in handling engineering projects and had worked in plant maintenance and engineering for over 20 years and was involved in machinery installation, maintenance and safety controls in equipment and overhead cranes. He has experience in overhead cranes maintenance, inspection and had trained industrial operators, foreign workers, crane operators and technicians from various organizations. He is NIOSH certified competent for Crane Rigging & Slinging.

COURSE CONTENT

DAY 1

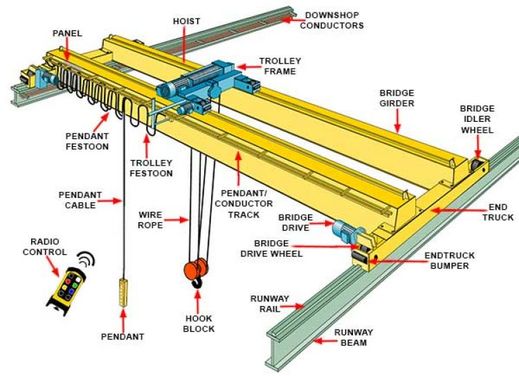

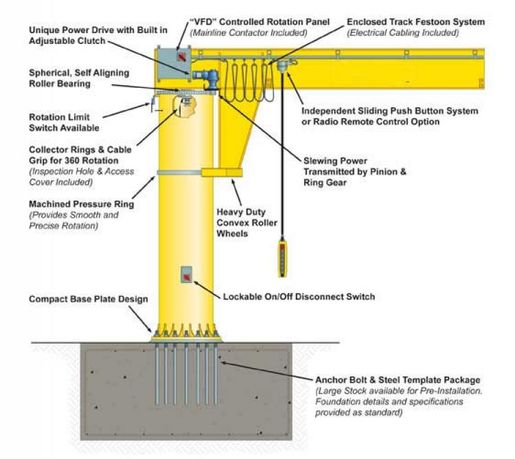

- Introduction to overhead crane

- Causes of crane accidents at worksite

- Employees responsibilities in safety

- Overhead Crane Safety Inspection

- Rigging, Lifting & Hoisting Safe Work Practices

- Types of lifting equipment, tools, lifting gears

PRACTICAL

. Inspection of Rigging & Slinging Equipment

. Overhead Crane Inspection at Site

. Rigging, Slinging & Lifting Loads

DAY 2

- Working Load Limit (WLL), Sling Capacity Tag

- Duties of rigger, signaler & crane operators.

- Types of Rigging Method & Lifting Gears

- Signaling for lifting operation.

PRACTICAL

- Individual assessment – Inspection, Rigging, Signaling & Lifting loads

- Inspection of lifting gears & Slings

- Overhead Crane Inspection at Site