5. MME Maintenance Of Mechanical Equipment

Topic 5 - EFFECTIVE PREVENTIVE MAINTENANCE OF MECHANICAL EQUIPMENT

INTRODUCTION

In industry the machines are important part of the manufacturing process to produce good quality product and services to customers. The machines also costs a lot more money and therefore, idle or down-time becomes much more expensive. Our industrial progress is being built around a capital intensive industry, with high productive capacity and high costs, and so it is very important that the machinery does not break down.

In this course participants will learn the principle of operation and the methods of doing proper maintenance in mechanical equipment, and also gain skills required to maintain them in satisfactory operation condition, thus reducing the machine downtime and increasing its reliability.

OBJECTIVE

After the completion of the course, the participants will:

WHO SHOULD ATTEND

This course is designed for:

DURATION

The duration of the course is 3 days. Classes will be conducted from 8.30 a.m. to 5.00 p.m.

DATE OF COMMENCEMENT AND VENUE

The course will be conducted on days/dates suitable to your organisation at your premises.

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia will be used as a guide.

COURSE FEE

Course fee …………………………………………………..

METHODOLOGY

Course will be conducted in form of class activities and practical approach at production floor.

COURSE CONTENT

DAY 1

-Split pins

-Circlips, Keys, Tap washers

-Spring washer

PRACTICALS

DAY 2

PRACTICALS

DAY 3

-Inspection methods

-Replacement methods

-Reliability Testing

PRACTICAL

INTRODUCTION

In industry the machines are important part of the manufacturing process to produce good quality product and services to customers. The machines also costs a lot more money and therefore, idle or down-time becomes much more expensive. Our industrial progress is being built around a capital intensive industry, with high productive capacity and high costs, and so it is very important that the machinery does not break down.

In this course participants will learn the principle of operation and the methods of doing proper maintenance in mechanical equipment, and also gain skills required to maintain them in satisfactory operation condition, thus reducing the machine downtime and increasing its reliability.

OBJECTIVE

After the completion of the course, the participants will:

- Realize the importance of implementing, and adhering to good maintenance practice

- Understand how preventive maintenance will help to prevent failures.

- Identify parts of rotating machinery, driver transmission and driven mechanical parts

- Carryout maintenance alignment and troubleshooting of belt drives chain drives, gear drives and couplings

- Know how to maintain, service and troubleshoot faults in Pneumatic system

WHO SHOULD ATTEND

This course is designed for:

- Maintenance executives

- Technician

- Maintenance Supervisors.

DURATION

The duration of the course is 3 days. Classes will be conducted from 8.30 a.m. to 5.00 p.m.

DATE OF COMMENCEMENT AND VENUE

The course will be conducted on days/dates suitable to your organisation at your premises.

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia will be used as a guide.

COURSE FEE

Course fee …………………………………………………..

METHODOLOGY

Course will be conducted in form of class activities and practical approach at production floor.

COURSE CONTENT

DAY 1

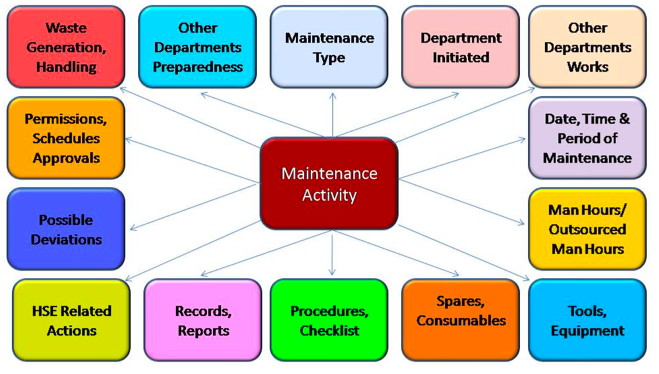

- EFFECTIVE MAINTENANCE PRACTICE

- definition and purpose of maintenance

- types of maintenance

- planned maintenance system

- SAFETY PRACTICES AND EQUIPMENT HANDLING

- Causes of accidents and impacts

- Hazards in mechanical equipments

- Unsafe work practice

- Unsafe workplace

- Responsibilities of employees

- Class Exercise – Causes of machine accidents

- THREADED FASTENERS

- Bolts, nut, washers

- Locking devises

- Thread Pitch gauge

- BSW and ISO threads

- Class exercise – Identify thread pitch

- LOCKING DEVICES

-Split pins

-Circlips, Keys, Tap washers

-Spring washer

PRACTICALS

- Inspection of locking devices in equipment

DAY 2

- MACHINERY MOUNTING AND ALIGNMENT

- machinery mounting and alignment

- installation, setting and leveling

- procedure for setting and leveling.

- HAND AND POWERTOOLS

- Hand Tools – Files, Hacksaw, Thread Taps, Spanners, allenkey

- Power tools – Hand grinder, hand Drill, Bench Drill, Bench grinder

PRACTICALS

- Marking and drilling holes

- Making internal thread

- Handling Hand and Power tools

- V BELT DRIVES AND TIMING BELT

- belt drives

- principles of operation, types and arrangements

- maintenance practices, failure patterns

- operating symptoms, symptoms found on inspection

- causes of failure and remedy

- CHAIN DRIVES

- maintenance practices

- alignment, slack adjustment

- installation of chain drives, chain removal

- cleaning, lubrication

- causes of failure and remedy

DAY 3

- PNEUMATIC EQUIPMENT

- Air Compressor

- Air dryer

- Air receiver tank

- Auto Drain

- Filter and Regulator

- Directional valves – 3/2 way. 5/2 way

- Single acting valve

- Double acting valve

- Air cylinder

- Practical – 1.Inspection of pneumatic equipment in factory

- COUPLINGS

- Principles of operation

- Types of couplings

- Maintenance practices,

- Failure patterns, operating symptoms

- check coupling alignment

- check condition of coupling

- SERVICING MECHANICAL EQUIPMENT

-Inspection methods

-Replacement methods

-Reliability Testing

PRACTICAL

- Disassembly, Inspection and assembly of equipment