1. Bearing Maintenance and Lubrication

Topic 1 - BEARING MAINTENANCE AND LUBRICATION

INTRODUCTION

Bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can handle. Poor bearing installation and lack of proper maintenance, results in major machinery breakdowns, which are losses business and customer services.

This course address every factor that impacts bearing service life. Emphasis is on understanding bearings and improving bearing performance, which in turn improves the reliability of equipment in which they are installed. By attending this training, participants will be able to do proper maintenance of equipment and prevent equipment breakdown.

TRAINING OBJECTIVE

The course objective is to provide skill and knowledge to improve the performance of rolling element bearings, which improves the reliability of rotating equipment. in the industry

WHO SHOULD ATTEND

DURATION

The duration of this course is 2 days

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

Classroom activities, discussion and site practical

COURSE CONTENT

DAY 1

INTRODUCTION TO BEARINGS IN EQUIPMENT

BALL BEARING

ROLLER BEARING

PRACTICAL AT WORKSITE

DAY 2

BEARING MOUNTING AND DISMOUNTING PROCEDURES

PURPOSE OF LUBRICATION

LUBRICANTS

METHODS OF APPLICATION

LUBRICATION MAINTENANCE

PRACTICAL AT WORKSITE (WORKSHOP)

INTRODUCTION

Bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can handle. Poor bearing installation and lack of proper maintenance, results in major machinery breakdowns, which are losses business and customer services.

This course address every factor that impacts bearing service life. Emphasis is on understanding bearings and improving bearing performance, which in turn improves the reliability of equipment in which they are installed. By attending this training, participants will be able to do proper maintenance of equipment and prevent equipment breakdown.

TRAINING OBJECTIVE

The course objective is to provide skill and knowledge to improve the performance of rolling element bearings, which improves the reliability of rotating equipment. in the industry

WHO SHOULD ATTEND

- Maintenance Technicians

- Operation Technicians

- Supervisors

DURATION

The duration of this course is 2 days

LANGUAGE

The course will be conducted in English and/or Bahasa Malaysia.

METHODOLOGY

Classroom activities, discussion and site practical

COURSE CONTENT

DAY 1

INTRODUCTION TO BEARINGS IN EQUIPMENT

- Purpose of Bearings

- Application areas of bearings

- Types of Bearings – Ball and Roller Bearings

- Bearing Load Factors

BALL BEARING

- Type, Specification and Sizes

- Construction of ball bearing

- Point contact and Line contact

- Causes of failures and remedies

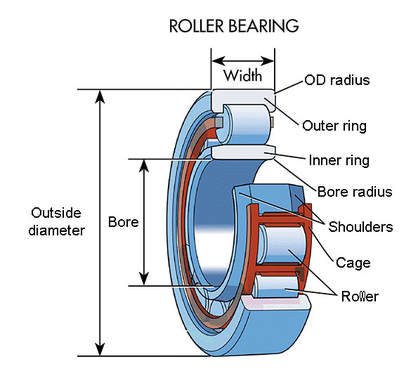

ROLLER BEARING

- Type, Specification and Sizes

- Construction of roller bearing

- Causes of bearing seizure and remedies

- Importance of radial clearance

- Maintenance free bearings

- High speed bearing

- Bearing maintenance in high temperature areas

PRACTICAL AT WORKSITE

- Inspection of Bearing Temperature

- Lubrication System Inspection

DAY 2

BEARING MOUNTING AND DISMOUNTING PROCEDURES

- Types of mounting

- Cold and Hot mounting methods

- Inspection of housing, shaft and bearing before installation

- Bearing inspection after installation

- Dismounting methods using hydraulic press

- Dismounting methods using pullers and extractors

- Method of removing seized bearing

PURPOSE OF LUBRICATION

- Friction and causes of friction.

- Frictional force and types of friction.

- Effects of friction.

- Types of wear.

- Disadvantages of friction.

- Coefficient of friction.

- Loss of power due to friction

LUBRICANTS

- Types of lubricants

- Properties of lubricants

- Types of liquid lubricants

- Solid lubricants

- Categories of greases

- Selection of lubricants

METHODS OF APPLICATION

- Selection and applications of lubricants.

- Lubrications systems.

- Types of lubricating oil pumps.

LUBRICATION MAINTENANCE

- Scheduling & Planning

- Mapping Lubrication Points

- Lubrication Contamination Control

- Oil Analysis

PRACTICAL AT WORKSITE (WORKSHOP)

- Bearing disassembly, inspection & installation

- Inspection of Shaft Runouts & Bearing Housing