7. Pump Maintenance

Topic 7 - Pump Maintenance TECHNOLOGY Training

COURSE CONTENT

DAY 1

- Main components of pump

-Classification of pumps

-Pump selection criteria

-Pump related symbols

- Class activity

-Pump power & efficiency

-Static head & friction head

-Cavitation

- Motor horsepower selection

- Pump assessment

- Class activity

-Components of pump

-Pump priming and operation

- Maintenance & Troubleshooting

- Class activity

-Components of pump

-Internal & External gear pump

-Maintaining gear pumps

-Maintenance & Troubleshooting

-Class activity

DAY 2

·Pump Seals & gaskets

·Hydraulic pump maintenance

COURSE CONTENT

DAY 1

- Introduction to Pumps

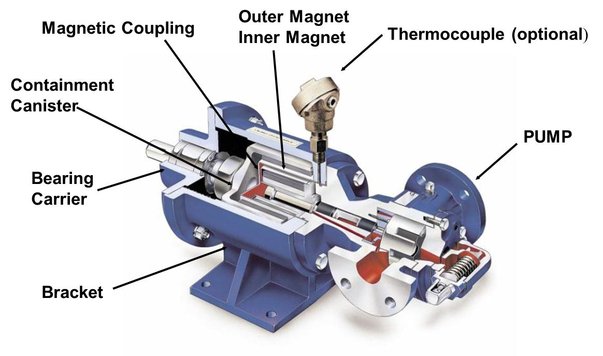

- Main components of pump

-Classification of pumps

-Pump selection criteria

-Pump related symbols

- Class activity

- Pump Performance Measurement

-Pump power & efficiency

-Static head & friction head

-Cavitation

- Motor horsepower selection

- Pump assessment

- Class activity

- Centrifugal pump

-Components of pump

-Pump priming and operation

- Maintenance & Troubleshooting

- Class activity

- Gear pump

-Components of pump

-Internal & External gear pump

-Maintaining gear pumps

-Maintenance & Troubleshooting

-Class activity

DAY 2

- Installation of Maintenance of Pump

- Couplings & alignment

- Pump installation

- Bearing maintenance

- Pump maintenance scheduling

- Class activity

·Pump Seals & gaskets

- 0 Ring

- Gland packing

- Mechanical seal

- Types and selection of gaskets

- Class activity

- Globe valve

- Butterfly valve

- Gate valve

- Check valve

- Relief valve

- Valve symbols

- Pressure gauge & Flow meter

- Class activity

·Hydraulic pump maintenance

- Hydraulic pump maintenance

- Oil viscosity & maintenance

- Oil powerpack construction

- Strainers & filters

- Oil coolant unit

- Causes of Hydraulic pump failures

- Oil contamination & cavitation

- Hydraulic pipings and hoses

- Basic hydraulic symbols

- Interpretation of hydraulic circuits

- Class activity