10. Maintenance Skills For Technicians

TOPIC 10 - MACHINE MAINTENANCE SKILLS FOR TECHNICIAN

INTRODUCTION

Breakdown occurs because we do not know what causes the breakdown or we do not find out the causes of the breakdown before replacing the defective parts. It is a proven fact that poor maintenance results in equipment failure. The causes of equipment failure may be due to hidden defects, which were not uncovered and rectified before breakdown actually occurs. Hidden defects such as dust, dirt, abrasion, looseness, leakage, corrosion, scratches, cracks, vibration, noise, etc are the abnormalities that lie beneath.

One major step towards achieving zero breakdown is to adopt a “self-initiated maintenance” or “autonomous maintenance”. The technician provides “first aid” as soon as the symptoms are noticed. This immediate action is required for safety reasons as well as preventing equipment deterioration.

Prevention is the fundamental role of maintenance. In comprehensive maintenance practices, technicians should look after the cleaning, oiling, bolting, servicing, minor adjustments and minor repairs such as attending to leaks, daily checks and preventive maintenance.

In this course, participants will learn various methods and skills to implement effective maintenance practices

WHO SHOULD ATTEND

This course is designed for:

COURSE OBJECTIVE

Upon completion of the course participants will be able to :

The training will be conducted in form of case study, group discussion and practical at the workplace.

The course will be conducted in English and Bahasa Malaysia will be used as guide.

DURATION

The duration of the course is 2 days

COMMENCEMENT DATE AND VENUE

The course can be conducted on days selected by your organisation

ASSESSMENT

A pre and post test will be conducted to assess all trainees understanding before and after attending the training.

Practical group assessment will be conducted and the results will be submitted together with training completion report.

COURSE CONTENT

DAY 1

SESSION 1 - DEFINATION OF MAINTENANCE

SESSION 2 – EFFECTIVE MAINTENANCE PRACTICES

SESSION 3 – AUTONOMOUS MAINTENANCE CONCEPTS

SESSION 4 – EQUIPMENT AWARENESS & MACHINERY SAFETY

DAY 2

SESSION 5 – CLEANING & INSPECTION STANDARDS

SESSION 6 – MACHINE OVERALL INSPECTION

SESSION 7 – LUBRICATION STANDARDS

SESSION 8 – TECHNICIAN VALUE ADDING ACTIVITY

INTRODUCTION

Breakdown occurs because we do not know what causes the breakdown or we do not find out the causes of the breakdown before replacing the defective parts. It is a proven fact that poor maintenance results in equipment failure. The causes of equipment failure may be due to hidden defects, which were not uncovered and rectified before breakdown actually occurs. Hidden defects such as dust, dirt, abrasion, looseness, leakage, corrosion, scratches, cracks, vibration, noise, etc are the abnormalities that lie beneath.

One major step towards achieving zero breakdown is to adopt a “self-initiated maintenance” or “autonomous maintenance”. The technician provides “first aid” as soon as the symptoms are noticed. This immediate action is required for safety reasons as well as preventing equipment deterioration.

Prevention is the fundamental role of maintenance. In comprehensive maintenance practices, technicians should look after the cleaning, oiling, bolting, servicing, minor adjustments and minor repairs such as attending to leaks, daily checks and preventive maintenance.

In this course, participants will learn various methods and skills to implement effective maintenance practices

WHO SHOULD ATTEND

This course is designed for:

- Production Technicians

- Maintenance Technicians

COURSE OBJECTIVE

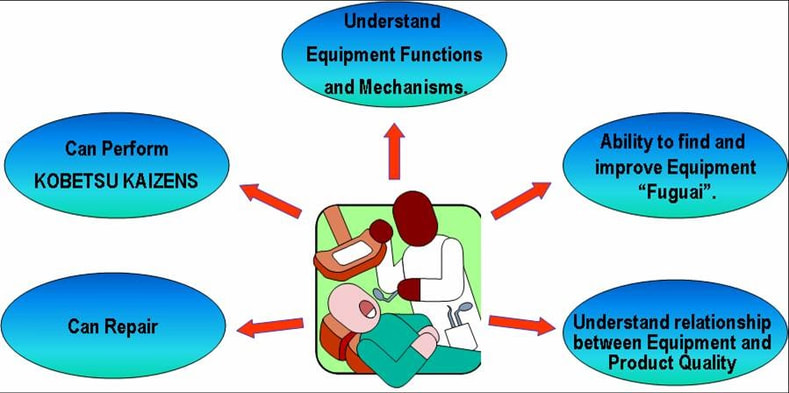

Upon completion of the course participants will be able to :

- Understand various types of maintenance

- Realize the importance of effective maintenance practices

- Understand the concepts of Autonomous Maintenance

- Perform restoration activity in machines

- Develop One Point Lessons (OPL)

- Contribute to SGA goals by sustaining value adding activities

- Use OPL to teach operators on machine function and equipment safety

- Understand the concept of MTBF & MTTR

The training will be conducted in form of case study, group discussion and practical at the workplace.

The course will be conducted in English and Bahasa Malaysia will be used as guide.

DURATION

The duration of the course is 2 days

COMMENCEMENT DATE AND VENUE

The course can be conducted on days selected by your organisation

ASSESSMENT

A pre and post test will be conducted to assess all trainees understanding before and after attending the training.

Practical group assessment will be conducted and the results will be submitted together with training completion report.

COURSE CONTENT

DAY 1

SESSION 1 - DEFINATION OF MAINTENANCE

- Purpose of Maintenance

- Responsibilities of technician

- Types of maintenance – Breakdown, corrective, preventive & predictive

- Causes of machine breakdowns

- 6 Maintenance evaluation criteria

- Class activity

SESSION 2 – EFFECTIVE MAINTENANCE PRACTICES

- Effective equipment maintenance

- The 7 major losses in manufacturing environment

- Tools and Material Control

- Autonomous Maintenance & implementation challenges

- Maintenance Performance – MTBF & MTTR

- Case Study & group activity

SESSION 3 – AUTONOMOUS MAINTENANCE CONCEPTS

- Definition of Autonomous Maintenance

- The 7 steps of Autonomous Maintenance

- Objectives, standards and approach towards AM

- Types of machine and equipment deterioration

- Importance of restoration before improvement

- Sustaining AM through small group activities (SGA)

- Class activity

SESSION 4 – EQUIPMENT AWARENESS & MACHINERY SAFETY

- Causes of accidents and impacts

- Machinery accident prevention methods

- Production Floor Practical -Identification of machinery potential hazards.

- OPL development methods and its use

- Application of OPL in Autonomous Maintenance

- Class practical - Developing OPL

DAY 2

SESSION 5 – CLEANING & INSPECTION STANDARDS

- Cleaning tools

- Cleaning is inspection

- The 5 Fuguai

- Class practical – Developing cleaning checksheet

- Class practical – Developing inspection checksheet and visual mapping

- Shopfloor practical – Hands on cleaning of machine / equipment and identification of problems and improvement points.

- Record and data collection of abnormalities

SESSION 6 – MACHINE OVERALL INSPECTION

- Fasteners

- Locking devices

- Pneumatic basic components – fitting, tubing, regulators solenoid valves, pressure gauge

- Bearings, seals and gaskets

- Gearbox oil level & oil leakages

- Abnormal noise detection & vibration inspection methods

- PRACTICAL – Developing overall inspection checksheet

- Group presentation – MY MACHINE IMPROVEMENT

SESSION 7 – LUBRICATION STANDARDS

- Importance of lubricant & lubrication

- Impacts of poor lubrication to equipment

- Oil viscosity, additives and oil analysis basics

- When, Where and How to lubricate

- Causes of early bearing failures and prevention methods

- Initial inspection and fault detection in rotating elements

- Practical – Developing lubrication chart and standards

- Production Floor Practical – Bearing inspection in rotating elements

SESSION 8 – TECHNICIAN VALUE ADDING ACTIVITY

- Machine Reliability Improvements

- Cost saving activities

- Machine Restorations

- Implementing visual controls

- Potential Failure Identification activity

- Group presentation – MY MACHINE IMPROVEMENT